Matchbox Tiger Moth - Tiger By The Tail

By Barney Dunlevy

One of my all time favourite aircraft is the DeHavilland DH82C and although I have built 4 of the 1/32 scale Matchbox kits over the years, I have never reproduced my old Moth as it was in 1955. I guess the big deterrent was the checkerboard pattern on the wings and tail, which I had masked off on the original..to the tune of 14 rolls of masking tape..and I was not about trying that again in any scale.

The first task was to find decal sheets in the correct size, but this proved to be futile. The tail surfaces required 3/32 inch and the wings 5/32 inch checkerboard decals..and no one produced the correct size until a question was posed on Hyperscale and Mike Grant of Mike Grant Decals responded with the answer. An order was placed and before too long the two sheets, 5X7, arrived in the mail and they looked really good. Perfect red squares on a clear background…which will be painted gloss white.

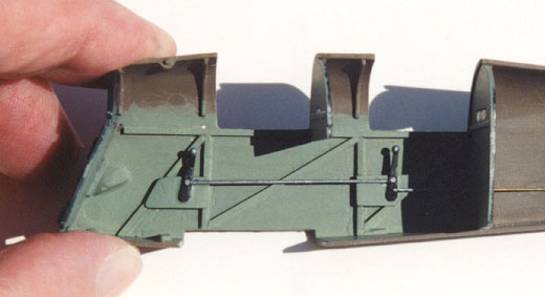

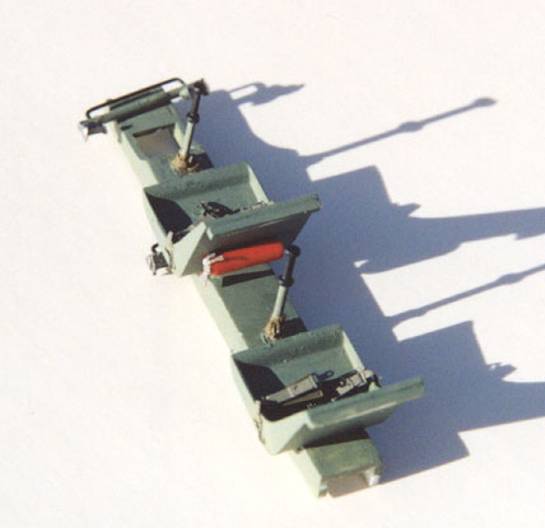

Now to the old kit that has been sitting in my closet for a great many years..and the much older factory drawings which I would use for reference. The major parts were cleaned up and checked for accuracy against the drawings. The fuselage is of course the British version with planned modifications for the Canadian built aircraft. The molded in structure and throttles looked out of place and sure enough the drawings confirmed my worst thoughts. Out came the trusty Dremel and soon I had all of the interior removed and replaced with Plasticard stock. The frame structure was replaced as were the throttle, brake systems, trim system, fuel shutoff and canopy emergency release.

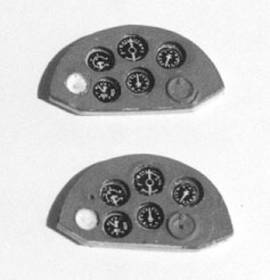

I did not like the kit instrument panels and they were the next to get the treatment, using two layers of plastic card with decal instrument faces. These were sealed with a couple of drops of Polyscale clear gloss. The seats were attached to the control tunnel on the floor but when I tried to fit things together I found that the seats were too wide and the tunnel was equally out of proportion. The seats were narrowed using Mr Dremel , new sides made from card stock and the new tunnel built up from .020 card. Rudder pedals were made up from brass bits and plastic rod and attached to the tunnel. A fire extinguisher was made by turning a piece of plastic rod in my battery powered drill and trimming with a nail board sanding stick. Bits of brass were used to finish the bottle which was installed on the back of the front seat. Eduard photo etch seat belts were attached to the seats and the whole parcel was installed in the fuselage. And it fit fairly well. The only kit parts in the fuselage are the firewall and the rear bulkhead which was properly modified.

The tail assembly next got my attention, with the rudder and elevators being separated from the fixed surfaces, and trim tabs installed. There were no trim controls on the kit even though they are quite prominent on the real thing.

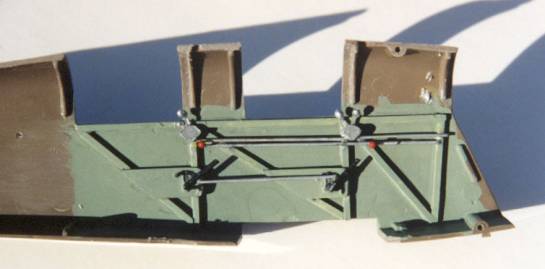

The wings got the treatment next , with the slats glued in place, filled and contoured. The Canadian Moth had a plywood leading edge covering over the ribs and this was taken care of with Tamiya grey putty. The bottom wing needed some extra attention with hand holds being drilled out and filed smooth. The aileron external control mechanism was finished using discs punched out of .010" card and glued in place. The fuel tank received a bit of enhancement using brass tube and plastic..more on this part later!

At this point, all rigging points and control cable exits were drilled out using a no. 72 bit in a pin vice. I plan on using stretched sprue for the rigging and control cables and by pre-drilling, the job becomes much easier.

The lower wings are now in place as is the tail assembly and tail wheel. The plan is to paint the model before installing the upper wing ..and apply the decals as well. What will it look like ..Well remember this was a civilian Moth, with my own personalized paint job..before the warbird restoration bug spread around the globe. My Tiger Myth was an eye-catching airplane and within the next couple of weeks, I'll be able to finish this work of love.

With the lower wing and tail assembly attached to the fuselage and the Tiger beginning to look like and aeroplane on its gear, it was time to start planning the paint and decal sequence. Using PolyScale Flat white, I sprayed the wing and tail surfaces that would get the checkerboard treatment and the cowling. This was masked off then the entire model was sprayed with PolyScale Deep Japan Yellow which was as close to RCAF Trainer Yellow as I could get in acrylic paint. The masks were removed and all components were sprayed with my favourite Gloss coat..Not Future, but again PolyScale.

Decals were next applied to the wings and tailplanes and I must say that Mike Grant Decals go on beautifully. The mouth and eyes were added to the cowling and set aside. If I were doing this again I would have Gloss coated the model before proceeding with anything else..just to protect the decals, which are very fragile.

Next came the struggle to attach the struts to the upper wing. The cabane struts were glued in place, the fuel shutoff assembly added and everything looked great. Until I tried aligning the upper wing to the fuselage! The 2.5 degrees dihedral in the upper wing had slowly sagged and with all the interplane struts in place, the cabanes looked to be about 3/16 inch too short..until I noticed the lack of dihedral. The trusty razor saw along the fuel tank/wing root took care of the sag and everything was glued up and set aside for a couple of days to harden thoroughly.

During the drying time for the fuselage/wing assembly, I started detailing the engine using photos of Bill Orbeck's Tiger as reference. Completion of this chore was not as gratifying because I noticed that the kit cowling was for the Brit version with no provision for a Canadian cowling. At this stage I said nuts!!! And closed up the cowling around my neat little Gypsy engine.

The canopy was tackled next. Polished and masked, I sprayed a couple of very light coats of Alclad II directly onto the bare plactic..Note the very light coats. Canopy handles attached, this was set aside while a Canadian exhaust system was fabricated from plastic rod and tube...

The cowling was next attached to the fuselage and the rigging was started. Initially I used stretched sprue, but not very impressed, I decided to switch to .015 steel wire. This went in very nicely...except for dropping each piece at least twice onto the Shag Monster That Eats Everything! Having predrilled all the rigging holes helped immensely.

Next came the control cables to the elevators and rudder..and here I found that CA glue is only instant when you get it on your fingers. This was frustrating to say the least. Next I fabricated the pitot/static system from brass rod and attached it to the starboard interplane strut. The fuel filler came next, then the fuel sight tube. This was made from predrilled clear sprue which was stretched then painted.

The entire aircraft was then sprayed with three coats, misted very lightly, of PolyScale Gloss Coat. With this dried, I put the canopy on the Moth and attached the prop. The last items required were the elevator and aileron counter balance weights. These were made from airfoil shaped strut material that I had been hoarding for many years, and repeated drops of MicroScale Krystal Kleer added for the weights. These were then painted gloss black and the monster was finished!!! After 3 months of daily work, my old Tiger Moth was finished. Not flawless, but certainly a fair reproduction of an airplane that I had owned so many years ago.

Would I ever do a project like this again? Probably not! It was too time consuming and at times very frustrating.

© Barney Dunlevy

This article was published on Wednesday, July 20 2011; Last modified on Saturday, May 14 2016