Icaerodesign | 1/32 Extra 330-SC

Reviewed by Mike Swinburne

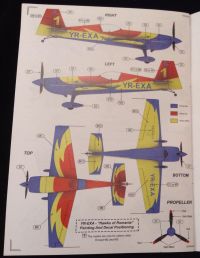

Icaerodesign is a resin kit manufacturer that is brand new to me. Based in Romania, their first(?) release is an Extra 330-SC aerobatic plane case in resin, with photoetch, a clear resin canopy, full engine, paint masks, and a nicely-printed set of decals to depict the bright aircraft on the boxtop. The kit can be purchased in the US from David Cooper at Coopers Models for around $100.

Opening the small box, I was impressed at the approach to the packaging. Icarodesign has a foam liner cut out to fit the parts, it appears as though the foam block was cut out with a hand tool. Large parts and the most delicate parts are wrapped in paper towel or tissue, and smaller resin parts are in zip-lock bags separated by area (engine, landing gear, etc). You'd have to try pretty hard to damage the parts in transit! An envelope contains the decal sheet, film instrument sheet, and photo-etch fret.

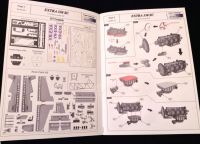

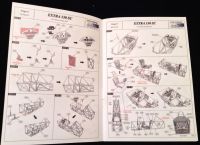

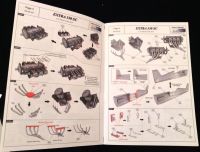

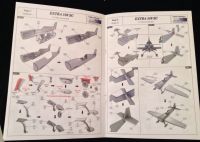

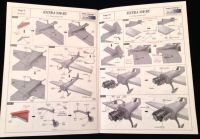

The quality of the castings and the detail included is absolutely stunning - easily on par with HpH, Fisher, and Silver Wings. The fuselage halves in my sample are in perfect alignment with no uneven shrinkage or warpage, and the halves even include small locator pins the size you'd expect to see on the best injection molded kits. A single piece canopy is included, molded in clear resin, and is extremely thin, barely thicker than a vacuum-formed canopy. There's a little bit of distortion on the lower sides of the canopy but the effect is nothing that would hide the interior detail. The instructions are very nicely done, also, with clear diagrams that should make building the kit about as easy as an injection kit.

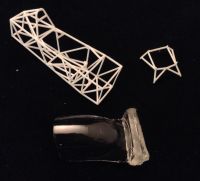

The biggest surprise to me was the inclusion of the entire interior tubular frame. Unlike the approach you may be familiar with such as in Silver Wings kits, the full structure is reproduced in one primary, and one secondary part. These were made in plastic a 3d printer and judging by the complexity, are printed fresh for each copy of the kit, not cast in resin from a master. Now with many parts made on a 3d printer, there is a bit of a grainy effect which is difficult to avoid unless using a 3D resin printer - use of such a tool would probably have doubled the price of the kit. Out of the box, these two parts should look good under a coat of paint but if you want to pose the canopy open, you will probably want to do a bit of careful sanding to smooth the parts down a little.

Dry-fitting major parts together, the wings fit perfectly to the fuselage, control surfaces line up correctly, and the gear appears as though it will be sufficiently strong despite having no visible wire reinforcement. Very impressive!

I'm going to let the photos speak for themselves - I'm going to go so far as to highly recommend this as a prime candidate for someone's first experience building a full resin kit.

© Mike Swinburne 2014

This review was published on Saturday, July 05 2014; Last modified on Sunday, November 15 2015