Videoaviation | 198432: 1/32 U.S. Navy Modern Tow Tractor

Reviewed by Thierry Laurent

I received recently a sturdy box in a thick padded envelope from Videoaviation. This contained their brand-new release: the 1/32 multimedia kit of the currently used US Navy shipboard tow tractor aka “STT”.

Many scale models of US deck tractors were released for the last twenty years but they typically corresponded to the various evolutions of the MD-3 tractors used on US carriers from the sixties up to the last versions (such as the A/S32A-31A) that appeared in the nineties. Moreover, many releases were short run ones and are accordingly not necessarily available or easy to get. It is a fact there is a cruel lack of large-scale tractor plastic kits.

This new release gives to the modeller interested in the last generations of Navy jets the possibility to re-create an accurate deck diorama with any of the available kits of the Super Hornet variants or the future F-35B or C kits that will be more than surely released in the future.

The primary role of the STT is the handling of aircraft aboard the flight deck of naval super carriers (CVN) and landing ships (LHA/LHDs). However, it is also used to provide a mobile platform and fuel source for the Jet engine Air Start Unit.

I joined to the review three pictures of the full-size machine (courtesy of US Navy) but for additional ones, please go to the Videoaviation product web page.

As mentioned above, the kit is packaged in a sturdy cardboard box. The top has a printed label showing a beautiful CAD-generated drawing of the tractor and driver. Note the drawing also shows two sets of wheel chocks on the tractor while they are not included in that reference.

Opening the box shows well packed contents protected by bubble wrap. The small components are gathered in three small zip locked plastic bags.

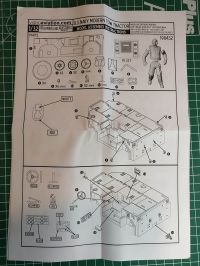

The kit is very simple. It is made of less than forty parts but captures well the look of the actual vehicle. The contents encompass a main body resin part, three bags for the other resin parts (wheels, small parts and driver parts), a small photo-etched set and a decal sheet. The box also contains four pages of detailed instructions printed on two A4 sheets of paper.

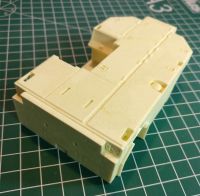

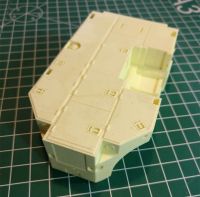

The body is nicely cast as a single part. The very fine anti-slip coat is even finely reproduced on the top of the vehicle. You have to look very closely to see it. This brick-shaped part needs close to zero clean-up as there is no huge casting block to remove from the undersides. Other companies should be inspired by such a customer care approach. Obviously, the classical resin casting method of the body of such tractors prevents reproducing any detail on the undersides. However, this is never an issue because the ground clearance is very low.

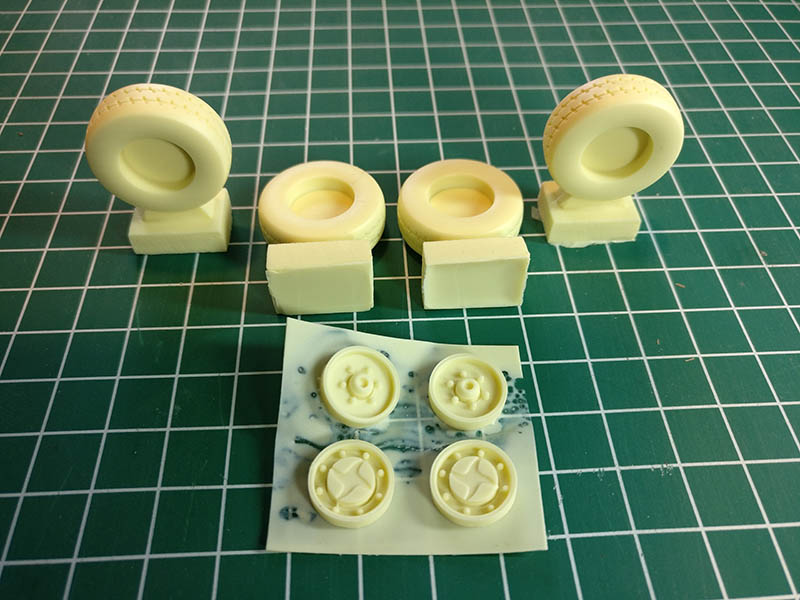

The wheels are quite simple as they are simply made of a rim and tire combination. They just have to be added on the axles moulded on the body. The tires look like the real ones with a similar pattern. However, the pictures I found of the full-scale ones show a higher number of horizontally engraved small slots in the tires but this is not really noticeable and this is possibly linked to casting limitations or may correspond to another tire variant. So, not a big deal.

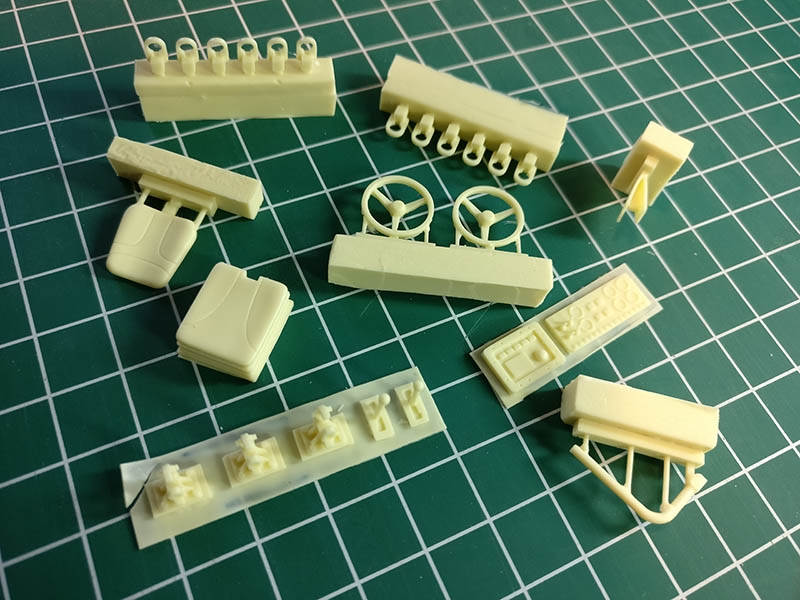

The other tractor parts are a steering wheel, the seat with its guard, the instruments panels, a pedal, a lever and some hooks including the towing ones. I also appreciated the producer added many spare copies of the small parts. This results in far less hassle if a small part is missing, not well cast or even lost by an absent-minded builder. Moreover, the spare parts box is always thanking the idea. This is another decision that should inspire other companies.

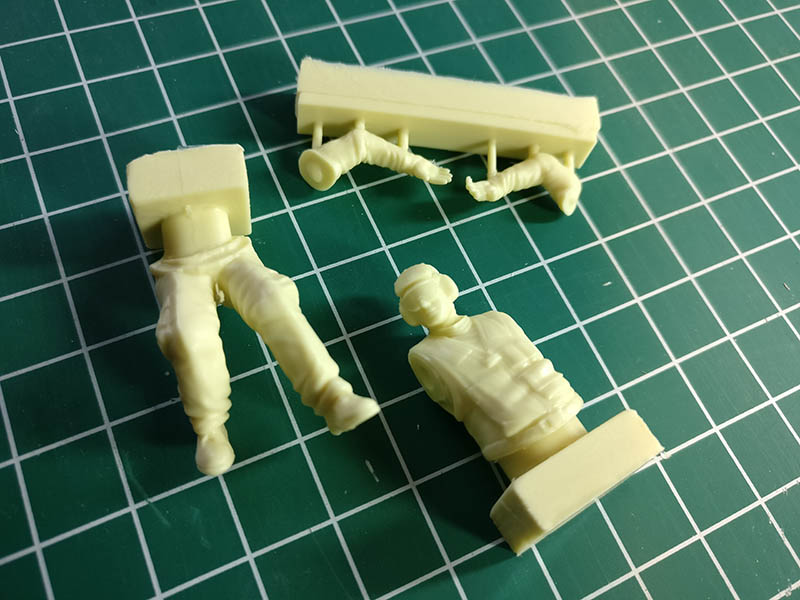

The last four resin parts are used to reproduce a driver in a lifelike relaxed pose.

Everything is smoothly cast without any bubbles or visible defects asking for more work than separating each part from its gate. Videoaviation clearly did its homework to design a kit asking for the minimum of effort to clean the parts.

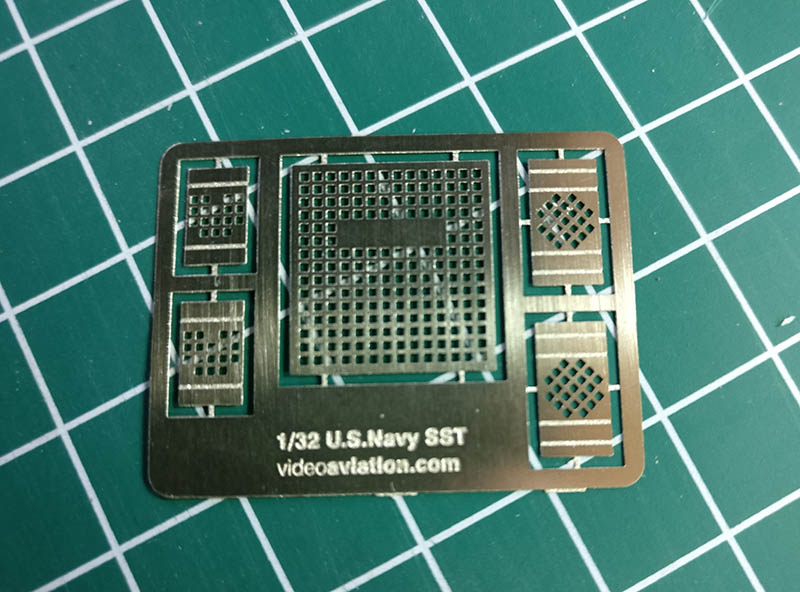

A small photoetched set is giving accurate radiator and light guards. Alas, the main radiator part does not have the SCHOPF name etched in its centre but I guess this is more than probably to avoid any infringement of the SCHOPF Maschinenbau GmbH trademark. For the people willing to solve that, custom printing the name in black on some paper decal would already improve the look. Last, the true nit-picker will want to recreate with a punch-and-die the heads of the small bolts securing each corner of the light guards.

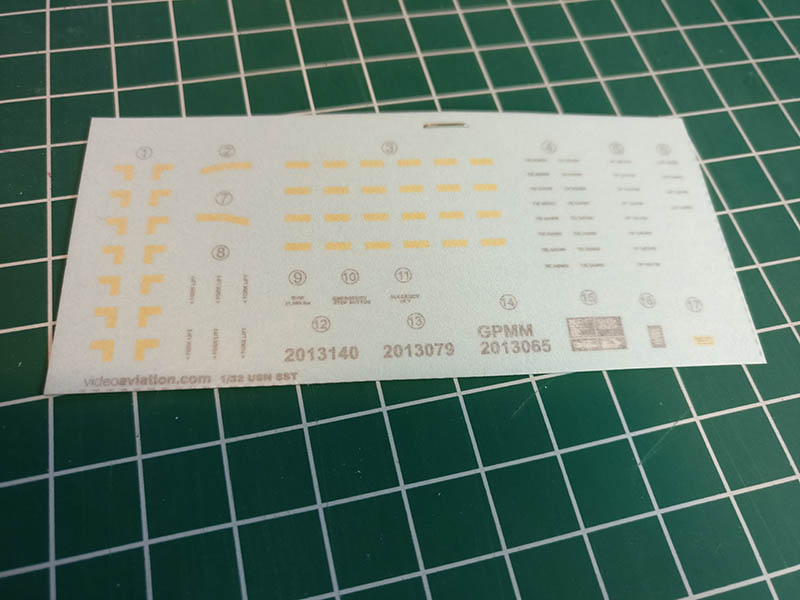

A small decal sheet is giving you some dozens of tiny decals to cover all the small markings visible on all sides of such white tractors. Serials for three STTs are included.

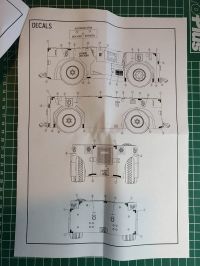

The black and white Videoaviation instruction sheets are clear and self-explanatory, giving exploded views of the assembly steps, painting guidance for the tractor and driver and scale plans to illustrated decal positioning. The review intentionally shows views of the instruction sheets as they are in the package. If you want to have a look at a PDF view of the instructions, simply download them for the product web page URL given here above.

For more explanation regarding the colours of the deck crew jacket, multiple websites give such details but you can already have a look on Wikipedia.

Regarding the painting instructions, I will just add an obvious remark: the anti-slip zones must be painted with flat black whereas all the other ones will require satin colours.

Conclusion

In conclusion, there are only very limited dimensions where such a product could be improved.

I hope Videoaviation will go on releasing such excellent products for a price range that stays very competitive.

Highly recommended.

Sample courtesy of Videoaviation.

© Thierry Laurent 2019

This review was published on Friday, November 01 2019; Last modified on Friday, November 01 2019